Delta Coating Facilities

Certifications and Standards

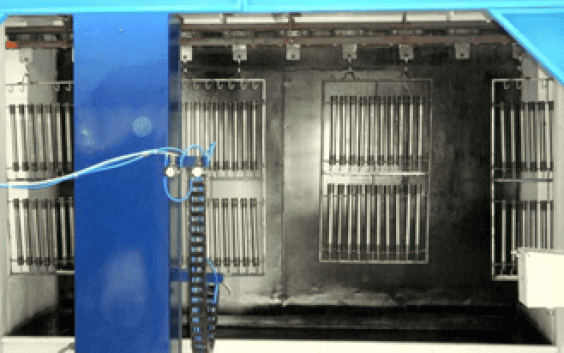

Delta MKS System as per CQI-12

Overview

The Delta Coating process is a vital part of enhancing the corrosion resistance and longevity of fasteners. At RFI, we use zinc flake-based coating systems such as DELTA®-TONE and DELTA®-SEAL, which are known for providing superior protection in harsh environments. Our licensor, Dörken MKS-Systeme, has developed these coatings to ensure long-lasting, environmentally friendly, and chromium(VI)-free protection for fasteners across various industries.

Step-by-Step Process

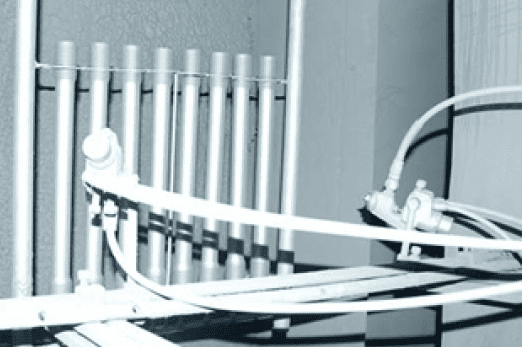

Base Coating

A zinc flake base coat is applied to the fasteners, forming the primary corrosion barrier. This coat provides excellent sacrificial protection, ensuring that the underlying metal remains intact even in corrosive conditions.

Top Coating

The fasteners are coated with a top layer that enhances durability, chemical resistance, and wear protection. This layer also provides additional corrosion resistance and adds an attractive finish to the fasteners.

Inspection

Each fastener is inspected for coating thickness, uniformity, and performance, ensuring that they meet the required industry standards and specifications, thus providing reliable and long-lasting protection against corrosion

Why This Process?

The Delta Coating process is crucial for providing long-lasting corrosion resistance and durability in industries such as marine, construction, automotive, and energy. By applying DELTA®-TONE and DELTA®-SEAL, the fasteners receive dual protection: a barrier layer that shields against corrosive elements and sacrificial protection from the zinc base coat. This ensures that fasteners can withstand harsh conditions while maintaining their structural integrity and performance over time. Additionally, the process is chromium(VI)-free, making it environmentally friendly and compliant with global standards. The coatings also enhance the fasteners' resistance to wear and abrasion, reducing the need for frequent replacements and ensuring cost-effectiveness. The Delta Coating system provides tailored solutions for various industries, delivering reliable protection and long-term performance in high-stress environments.

.png)