Heat Treatment Process

Certifications and Standards

ISO 9001:2015 Certified

AMS 2750 Heat Treatment Standards

Overview

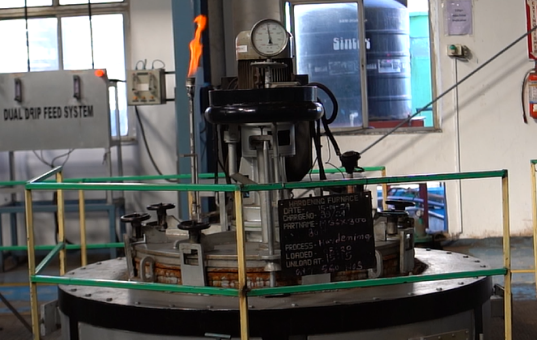

Heat treatment is critical to achieving the right mechanical properties like hardness, toughness, and strength in fasteners. At RFI, we utilize a pit-type heat treatment furnace which is ideal for long components, ensuring uniform heat distribution and high precision. Our SCADA-controlled system allows us to precisely control the heating process, resulting in consistent product quality.

Step-by-Step Process

Loading

Fasteners are placed in the pit-type furnace, ready for heat treatment.

Heating

The furnace heats the fasteners to a specific temperature for metallurgical transformations.

Cooling

The fasteners are cooled at a controlled rate, adjusting hardness, toughness, or ductility.

Why This Process?

Heat treatment is vital for improving the mechanical properties of fasteners, ensuring they can withstand extreme forces and harsh environments. By precisely controlling heating and cooling, we enhance the strength, toughness, and durability of the material, preventing structural defects and improving resistance to wear, fatigue, and deformation. This process refines the internal structure of the fasteners, relieving residual stresses and ensuring uniform grain structure. It allows us to tailor hardness and ductility to meet the specific needs of different industries, such as aerospace, automotive, and renewable energy, where high-stress and dynamic conditions require reliable performance. In short, heat treatment ensures that our fasteners deliver superior strength and durability, making them fit for the most demanding applications across various sectors.

.png)