Forging Facility

Certifications and Standards

ISO 9001:2015 Certified

Meets SAE J429 and ASTM Standards

Overview

Forging is a key process in manufacturing fasteners that require superior strength and fatigue resistance. RFI’s state-of-the-art forging facility shapes metal under high pressure, creating fasteners that align the metal’s grain structure, significantly enhancing mechanical properties. This meticulous process not only improves the overall durability of the fasteners but also ensures consistent performance in demanding applications. By utilizing advanced forging techniques, RFI delivers products that meet the highest industry standards, providing reliability and confidence to our customers.

Step-by-Step Process

Material Selection

Raw materials are cut into billets or blanks.

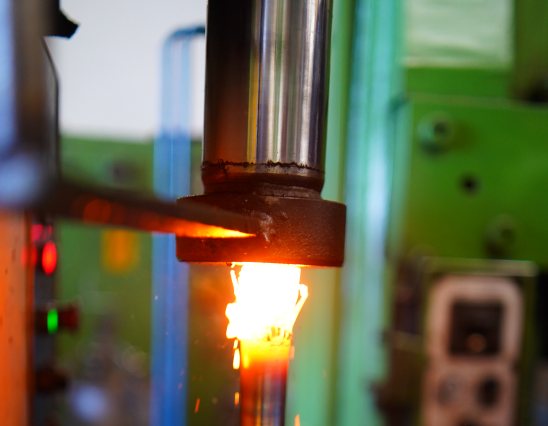

Heating

The material is heated to an optimal forging temperature for shaping.

Forging

The metal is shaped in a die under high pressure, refining the grain structure.

Finishing

Threads are rolled or cut, and final heat treatment or coating is applied.

Why This Process?

Forging enhances the strength and durability of fasteners, making them well-suited for high-stress and high-load environments. The forging process aligns the metal's grain structure, improving the overall toughness and mechanical properties of the fasteners. This results in components that can withstand heavy forces, impact, and wear, making them ideal for industries such as automotive, construction, and aerospace. Additionally, forging offers superior precision, ensuring that fasteners are manufactured with exact dimensions and tight tolerances. This precision leads to better fit, increased fatigue resistance, and overall reliability, which is critical for fasteners used in critical applications. The combination of strength and accuracy makes forging a preferred method for producing high-performance fasteners.

.png)