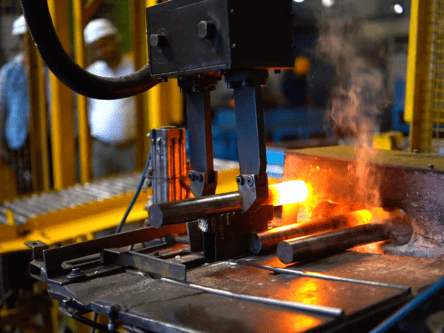

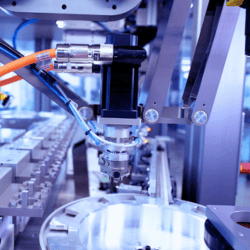

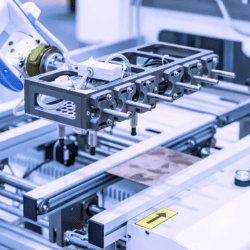

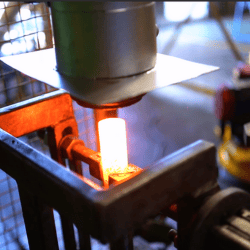

About the Robotic Arm

The Future of Precision Manufacturing

Introduction: RFI is embracing Industry 4.0 by integrating state-of-the-art robotic arms in our fastener manufacturing process. These robotic systems are designed to enhance precision, consistency, and efficiency, ensuring our products meet the highest industry standards.

Contact Us

.png)