Inspection Processes

Rigorous Inspection Processes for Unmatched Quality

At Randack Fasteners India, our commitment to quality extends through every stage of the manufacturing process, with a strong emphasis on inspection and testing. Each fastener must meet strict industry standards, and that’s why we have developed an in-depth inspection process as part of our quality assurance protocol. Our fasteners undergo stringent tests, including torque testing, tensile testing, hardness testing, chemistry testing, and impact testing to meet or exceed the demands of industries such as aerospace, oil & gas, construction, and energy.

Why Our Inspection Process Matters

At RFI, inspection is not just a step in the process; it’s an essential element that guarantees product reliability and safety. By thoroughly testing each fastener, we ensure:

- Compliance with Industry Standards: Our testing procedures meet international standards and customer-specific requirements.

- Durability & Strength: Ensuring fasteners withstand stress, load, and environmental conditions without failure.

- Safety & Reliability: Particularly for critical applications, we ensure that fasteners perform consistently, reducing the risk of malfunction.

Our Inspection Process Includes

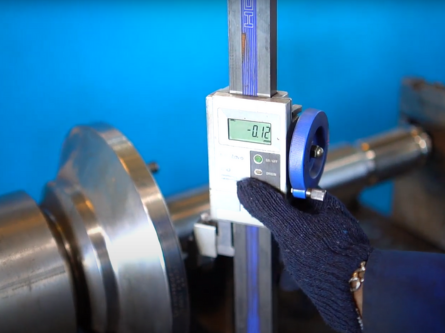

Torque Testing

Ensures fasteners meet necessary torque specifications required for critical applications, particularly for high-stress environments like automotive and aerospace.

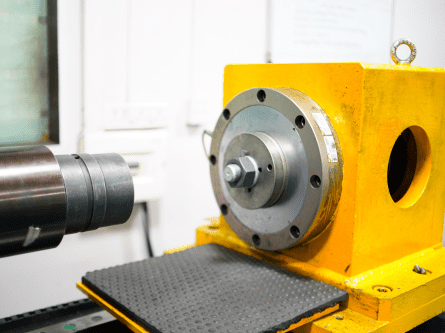

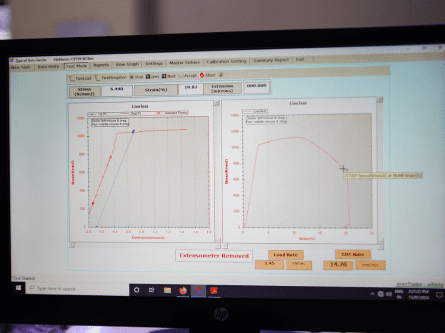

Tensile Testing

Measures the strength of fasteners by stretching them until they break, determining the maximum tensile strength and elongation properties.

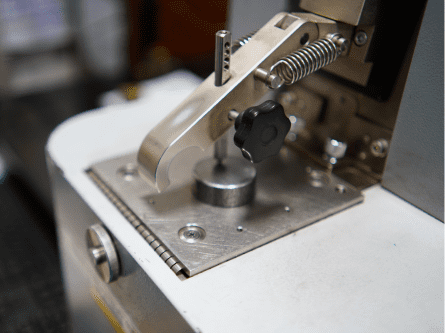

Hardness Testing

Evaluates the material's resistance to deformation, ensuring the appropriate level of hardness required for wear resistance and durability.

Chemistry Testing

Verifies the material composition of fasteners by analyzing chemical elements in raw materials to ensure consistency, strength, and corrosion resistance.

Impact Testing

Evaluates fasteners’ ability to absorb energy and resist fracture when subjected to shock loading, even in extreme conditions like sub-zero temperatures.

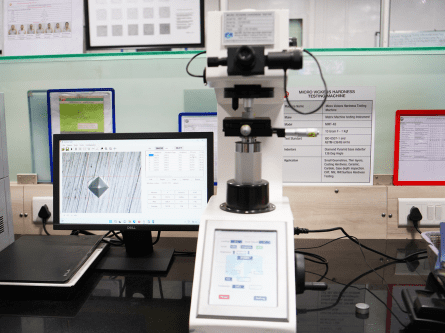

Advanced Inspection Equipment

Our inspection process uses cutting-edge technology like Coordinate Measuring Machine (CMM) and Non-Destructive Testing (NDT) to ensure precision and reliability.

At Randack Fasteners India, our inspection processes are followed strictly, ensuring that every fastener meets the highest quality standards before leaving our facility. These tests guarantee that our fasteners are reliable, durable, and fit for critical applications across various industries.

Advanced Inspection Equipment

At RFI, our inspection process is powered by advanced equipment and cutting-edge technology to guarantee precise and reliable results

.png)

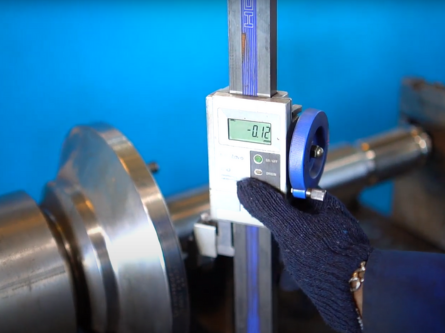

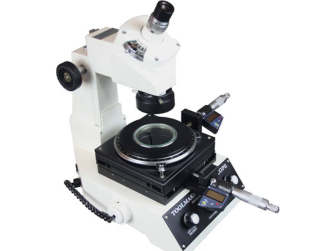

Coordinate Measuring Machine (CMM)

For detailed dimensional verification of fasteners, ensuring exact compliance with design specifications.

.png)

Non-Destructive Testing (NDT)

Techniques like Magnetic Particle Inspection (MPI) and Ultrasonic Testing (UT) allow us to detect surface and subsurface defects without causing damage to the fasteners, preserving product integrity.

Microscopes and Micrometers

To perform detailed surface analysis and ensure there are no structural irregularities or imperfections in the fasteners.

Our Inspection Protocol

At Randack Fasteners India, our inspection processes, including torque testing, tensile testing, hardness testing, chemistry testing, and impact testing, are strictly followed as a protocol to ensure that no fastener leaves our facility without meeting the highest standards of quality. Each of these tests plays a crucial role in verifying that our fasteners are reliable, durable, and fit for use in critical applications.

.png)